What is a robotic arm? The most common industrial manipulator robot or “robotic arm”, consists of several segments, connected to provided stepper motors or servo motors, controlled by a computer. An effector device is located on the working part of the hand, that directly interacts with objects. Most often, an effector is one of many possible gripping devices, which can be purchased here https://sprenergo.com.ua/644229303-pnevmatychni-zakhopliuvachi/, or an object manipulation tool. About grabbers for robots, read their varieties and applications in this article.

Fascinating devices for robotic hands

A robot effector is the physical interface between the robot arm and the workpiece. This tool at the end of the hand is one of the most important parts of the robot.

Capture is a type of effector, designed to hold and move parts. Enters into direct contact with the object, therefore, it is important to choose the right type of grip, which is most appropriate for the target objects, which will be able to reliably hold and not damage the target.

Robotic arms often have built-in sensors, which inform the computer, how much the robot grabs a certain object. This prevents the work from dropping or breaking the part.

Other types of effectors:

- welding, milling or drilling equipment,

- screwdrivers and nut drivers,

- paint sprayers or special grippers for certain types of objects, 3D-printing extruders, construction tool.

There are also anthropomorphic delights, that repeat the brush of a human hand, but they are hardly used in industry (as long as anthropomorphic robots are not involved in production), and intended for research and medical purposes, for example, as part of prostheses.

Today, developers follow two fundamentally different approaches to designing effectors:

- Universal grips for any type of tool or task.

- Quick-change highly specialized grips.

Each approach has its advantages, and disadvantages, therefore, designers of robotic productions have to take into account the economic feasibility of both approaches. Today, highly specialized hobbies are the most common.

Types of captures

Hobbies are distinguished by the following types:

- According to the principle of action:

- mechanical;

- magnetic;

- vacuum;

- with elastic pneumatic or hydraulic chambers.

- Based on the nature of the objects:

- are based (move objects to a given area);

- rebasing (able to change the position of objects, including in relation to themselves);

- centering;

- supporting;

- fixing.

- By the nature of the attachment:

- indispensable;

- variables;

- fast changing;

- with automatic replacement.

- By type of management:

- uncontrolled;

- team;

- hard programmed;

- adaptive.

- By type of sponges:

- tough;

- adjustable;

- elastic;

- plastic.

- By drive type:

- spring;

- pneumatic;

- hydraulic;

- electromechanical.

How to choose a catcher

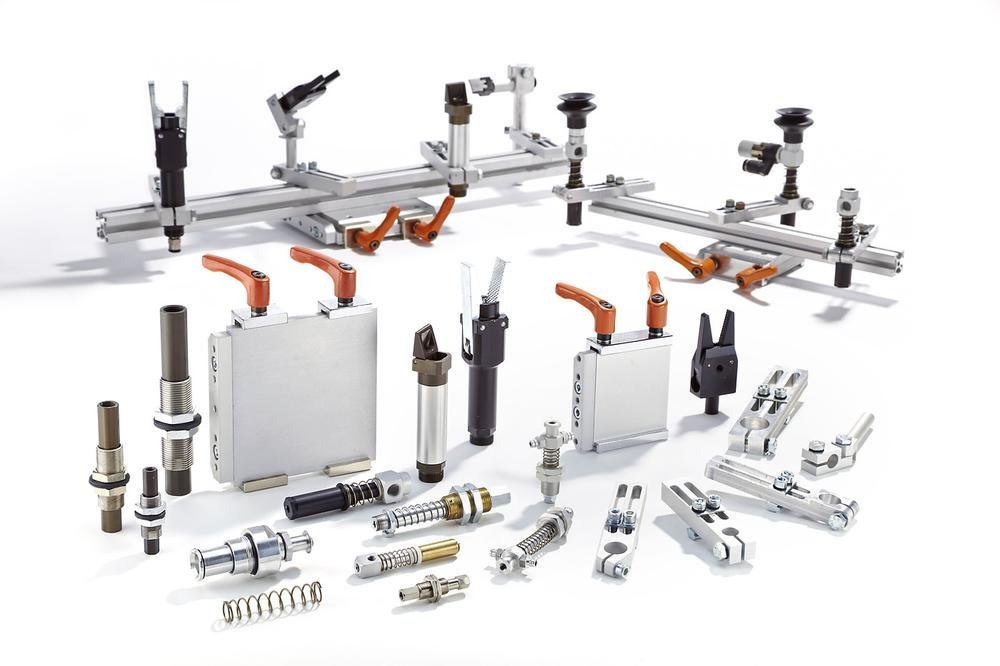

Completeness and important schemes can vary greatly from manufacturer to manufacturer. Consider a typical classification from the example of Gimatic.

EOAT assembly is performed using a separate program, which automatically takes into account all the necessary equipment when choosing. Each part of the EOAT is equipped with an RFID tag, namely the capturer-RFID-controller, which automatically reads labels and prevents incorrect assembly.

The EOAT consists of a robot-side device and a gripper-side device, control device (the controller), interface cables, pneumatic or electric system. in addition, the grabber can be equipped with an additional suspension, sensors, linear drives and guides, a separate power supply unit, braking system.

A pneumatic/electric gripper rotation device is responsible for:

- rotation;

- incline;

- turn;

- turn the table.

The devices are intended for rotation, tilt or turn as the grips themselves in different modes, yes rotation of the table with detail.

Device for quick change of the grabber with and without a safety valve:

- RFID identification module;

- setting up a quick change of grip on the part of the robot/gripper;

- device of automatic centering from the side of the robot/grabber;

- pneumatic drive of the quick change grip device;

- device for quick change of grip with springs.

This type of device provides a quick change of grip on the robotic arm, control of the correctness of the configuration, overpressure protection, compatibility with robots of various manufacturers.

Modular grabber:

- EOAT mounting base;

- assembly kits.

Allows you to independently create grabbers of any size from components, of different types and carrying capacity.

Parallel pneumatic/electric grippers:

- They have high accuracy, repeatability and load capacity within the widest limits. Can be additionally equipped with other equipment, for example, a drilling or welding unit.

Angled pneumatic/electric grippers:

- They have great compression, that applies, example, for cutting metal. On the other hand, the possibility of using different sensors makes it possible to work with the detail very delicately and precisely. As well as parallel grips, corner ones can be equipped with additional equipment.

Catchers with inflatable chambers:

- Indispensable when working with fragile objects, example, for moving glass jars or bottles, porcelain, laboratory glass. They can fix the part as outside, and from the inside.

One-finger grips:

- pneumatic grabbers;

- angular pneumatic grabbers;

- perpendicular pneumatic grippers.

Pneumatic magnetic gripper:

- Radial pneumatic/electric grippers:

- In terms of purpose, they are similar to angular ones, but, usually, have the possibility of self-centering.

- Three-beam pneumatic/electric grippers:

- Designed for reliable fixation of cylindrical parts.

Vacuum grabbers:

- Used for work with fragile and smooth parts, example, with automotive glass or polycarbonate sheets.

Capture sensors:

- Magnetic;

- Inductive;

- Ultrasonic;

- Optical;

- Analogues;

- Overload;

- For fragile parts.

Application cases

Automation of quality control, DIEHL Aerospace , Germany

Diehl Aerospace manufactures computer systems for the Airbus A350 XWB. After receiving a large contract, the company's management faced the task of dramatically increasing the productivity of the quality testing department. There was a choice: add an expensive night shift of "live" employees, extend the term of the contract or automate a number of processes.

Diehl Aerospace chose the Universal Robots UR10 robotic manipulator , equipped with a pair of Robotiq 2F-85 adaptive grippers and an FT torque sensor 300 for automation. The robot is responsible for precisely inserting the fragile computer case into the test equipment, and each electrical interface, Exit, output and sensor are double-checked.

Assembling capsules for coffee machines, GIMATIC в TECMES

Tecmes was not satisfied with the current quality and low speed of capsule assembly, uneven compaction of coffee powder and high energy consumption of existing equipment. For this reason, the company, based in Vaiano Cremasco (Vajano-Kremasko commune, region of Cremona, Lombardy region, Italy), turned to Gimatic to supply pneumatic grippers for capsule positioning and movement.

This is basically the XP20-A model – the grabber is designed for the needs of the food industry. The XP20-As feature stainless steel jaws and acetal resin guides. The latter is necessary for proper sealing and preventing the ingress of coffee powder (and other products in food production) in the mechanism of the grabber. Gimatic also equipped Tecmes with highly efficient compact grippers (SGPs are energy efficient 95%) and high-speed grippers (HS work with frequencies from 5 to 6 Hz).

Automation of glass polishing, Saint-Gobain , France

At the Saint-Gobain factory in Sully-sur-Loire, France, the use of human labor led to a high cost of the finished product. In an effort to make production more efficient and free employees from tasks, that are repeated, the Saint-Gobain company wanted to automate the tedious process of polishing glass. To solve the problem, it was necessary to program complex movements, which are different for each small series of glass products.

Using the Robotiq FT torque sensor trajectory recording 300 , the operator shows the device a sequence of movements, Universal Robots UR10 records and then plays back the movement of the operator. This increases the speed and accuracy of processing, what, finally, significantly reduces the cost of production.

Conclusions

Choice

There are no universal delights, that would handle any job equally well—the robot grips used must be size-appropriate, weight and rigidity of objects, with whom they work.

As with works in general, developers and users must consider very different, numerous requirements that sometimes contradict each other - in terms of work speed, accuracy, power of influence, the shape of the detail, type of work performed and ensuring safety.

Robotics suppliers are increasingly offering complex solutions, covering a wide segment of tasks, including sensors and software. Much attention is paid today to the development of effectors, which are easy to install and use, and can also be installed on manipulators of any manufacturer.

Prospects

Among the latest trends in the development of robotic manipulators is the use of artificial intelligence, which makes it possible to achieve even greater simplicity and speed of teaching the robot the necessary actions, flexibility in solving complex tasks. The scope of use is also expanding: according to the Robotics Industry Association, use of EOAT in 2017 increased by 14% in the automotive industry and to 20% in other areas.

Modernization of enterprises with the use of automated systems significantly increases productivity, that is why the use of robotics is a mandatory element of the development of any production, which provides not only competitive advantages, but also most often the very survival of the business.