Worm gear – a mechanism for increasing or decreasing the speed of rotation using a worm gear (gears with perpendicular axes, lying in two different planes).

Worm gear design

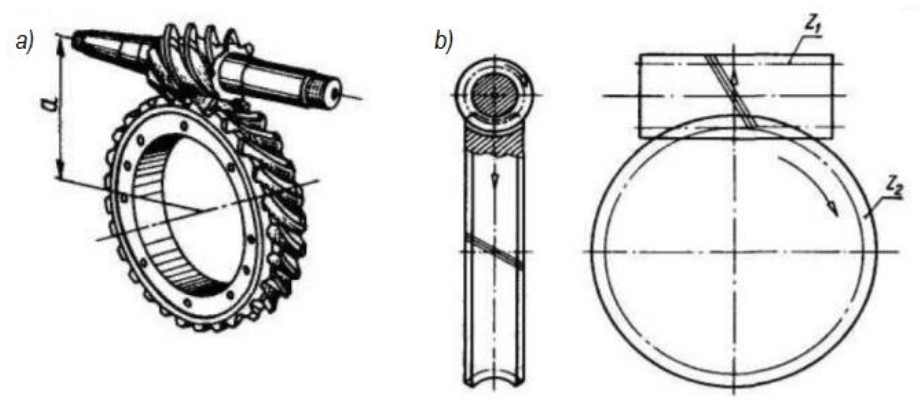

In the picture below, you can see a simple worm gear implementation..

The main advantages of this solution:

The main advantages of this solution:

- high gear ratio;

- self-locking (if necessary);

- quiet operation.

The main drawback: very low efficiency (0,5), hence the need to ensure good lubrication.

The transmission of power in such a transmission is frictional. Power flow direction is important here. If the leading element is a worm, The transmission efficiency is determined by the ratio:

- η = tg γ / tg (c + ς)

Where:

- c – thread shear angle, ς – "Angle of friction" is, that the coefficient of friction μ = tan ς.

Similarly,, when the driving element is a worm wheel, The transmission efficiency is expressed by the formula:

- η = tg (c – ς) / tg γ

It's easy to see here, that γ <ς, Transmission efficiency less than zero, which means, that there is no possibility of transferring the drive in this direction, ie. self-locking.

If you are looking for a worm gear, pay attention to the assortment of the online store GrizliCnc https://grizlicnc.com.ua/reduktory. It is worth noting, that worm gear works well in stepper motors.

note, under certain conditions, the worm gear is a self-locking mechanism. This is also a disadvantage, and advantage. Self-locking can happen accidentally, eg, due to insufficient lubrication, when the coefficient of friction exceeds the permissible limit, and the transmission is in the self-locking range.

This feature may also be desirable, and in this case the worm gear acts as a transmission in one direction and as a brake in the other. The mechanism created in this way is used, eg, in screw lifters and in the tensioning mechanism of the guitar string.

However, the self-locking of the worm gear cannot be considered as a brake in the system., especially in the case of hoists or winches, where security considerations matter, because, if the drive system with a suspended load accelerates and we switch off the drive, the load will not stop in adverse conditions, but will fall down (will act on the system by accelerating it).

Using worm gears

Gears can be used, if we want to transmit torque at an angle 90 . They can be used to drive, that is, to transfer power from the active shaft to the passive shaft. Worm gear can be used in indexing devices, such as dividing head, drive of a table of a milling machine, etc.. d. They can also be used in devices for manual rotation or steering.. Worm gears work well in stepper motors.