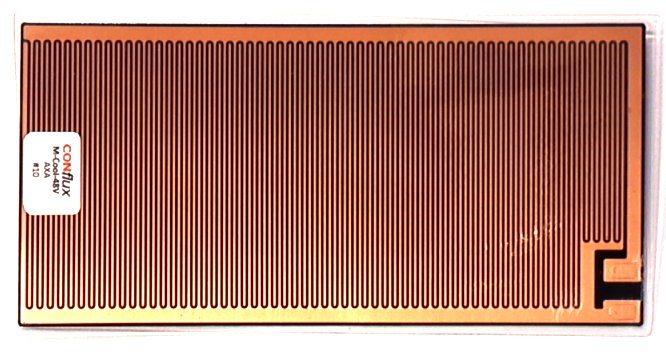

The heating element converts electricity into heat by resistive or joule heating process. The electric current passing through the heating element is resisted, with the result that it heats. In contrast to the thermoelectric effect, this process does not depend on the direction of current flow.

Metallic materials used in heat

- Nichrome: the overwhelming majority consists of nichrome 79/21 (79% nickel, 21% chromium) such heating elements Fastov, made in the form of a wire, Ribbon or strip. He is a top quality material, because it has a relatively high resistance and forms a layer of chromium oxide when heated for the first time. Material under this layer is not oxidized, and protected from destruction and burnout.

- metal resistance: metallic resistance heating elements may be in the form of a wire or ribbon, straight or spiral. They are used in general heating devices, such as heating elements, toasters, hairdryers, furnace for industrial heating, floor heating, roof heating(to not formed icicles), heating trails(to melted snow and ice), dryers, etc..

The most common materials used for the manufacture of heaters in Fastov at ALC "Electric Heater":

- Nichrome – Wire and strip;

- German silver (copper-nickel) – alloys for heating at low temperatures.

ceramic heating elements

Ceramic refractory materials andhav e low density, temperature melting is 2030 °WITH. at high temperatures they form a dioxide silicon, protecting metal from further oxidation. Region the use of heaters It includes:

- the glass industry and manufacturing pottery;

- oven heat processing;

- production of semiconductor circuits.

Composite heating elements

Tubular heating elements

Tubular elements usually consist of coils or thin nichrome resistive heating to the alloy in wire form, which is in the metal tube (stainless alloys, such as Incoloy, or copper) and a powder insulation(magnesium oxide).

To maintain a constant humidity in hygroscopic insulator, ends are equipped with an insulating material, for example ceramic or silicone rubber, or combinations thereof. The pipe is pulled through a die to compress the powder and the maximum heat transfer. They can be direct(in toaster), or a curved shape to cover the heated space(eg, in electric ovens and coffeemakers).

Polymeric heating elements

Resistive heaters may be made of rubber-conductive PTC material, wherein resistance decreases with increasing temperature. Such a heater will generate high power for heating the water when it is cold and constantly maintain the desired temperature.

In connection with a decreasing specific resistance heater, a heating element will never be able to produce more heat than necessary. When heated to a certain temperature, PTC materials act as an electrical insulator and do not pass current., then naturally stop heated. Temperature can be selected in the manufacturing process, Typical temperatures are between 0 and 80 °C (from 32 to 176 ° F).

Thus heating element made of polymeric material is self-regulating. This means that it will maintain a constant temperature without the need for control electronics. Self-limiting assumes that the heater is not able to exceed a certain temperature and does not require protection against overheating.

A source: http://elektronagrevatel.com