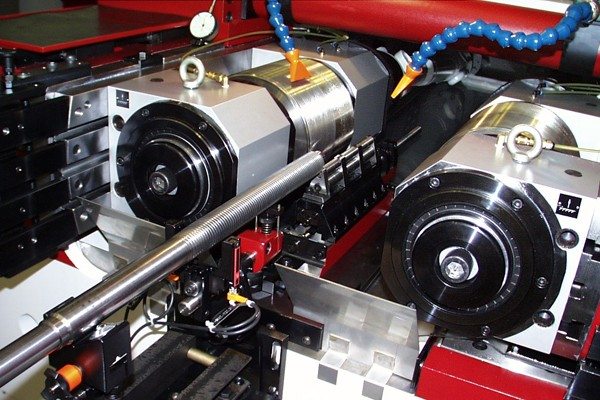

Thread rolling is cold-worked round billets, which is positioned between two spinning shafts and watered oil. The advantages of this type of manufacturing thread may include a significant increase in strength, very good values of roughness on the carrier surfaces and the thread speed manufacturing.

thread rolling It is a plastic working method, carried out generally at cold. With this method it is possible to create a thread of different size. Depending on your needs, you must find the right tools and materials.

A very important issue is the proper selection of the diameter of the workpiece, which will be rolled thread. From it the diameter of the final product depends. It will be appreciated that when the preform is a large pressure between the rolls is performed on it, under the influence of which the movement of the metal and the formation of the thread. If the diameter of the preform will be too small, the tip of the thread can not be fully formed. If there is too much risk of damage to tool or manufacture of threads with incorrect dimensions.

The main advantage is, what thread rolling work devoid of chips, which is present in the processing method of cutting. This results in non-waste production, and the finished product is different durability, because the metal is not destroyed because when cutting during processing, moreover material further strengthened with knurling, that causes an increase in thread strength. At its manufacturing manages to keep a very low roughness, which is impossible in the case of processing by cutting.

The disadvantage of plastic processing is the ability to thread rolling only on easily deformable materials. This causes difficulties in processing certain materials. In their case,, the best way is to use the cutting processing.

"SpetsKrepezha Leningrad plant" It provides application thread rolling using high-tech tools. This makes it possible to optimize the process. Using special tools ensures production rate, so that it is able to provide short lead times. Thread thus produced is of high quality and precision. So if you are in need of these services do not loiter and contact the following phone numbers: St. Petersburg: +7 (812) 363 06 62; Moscow: +7 (495) 003 37 62.