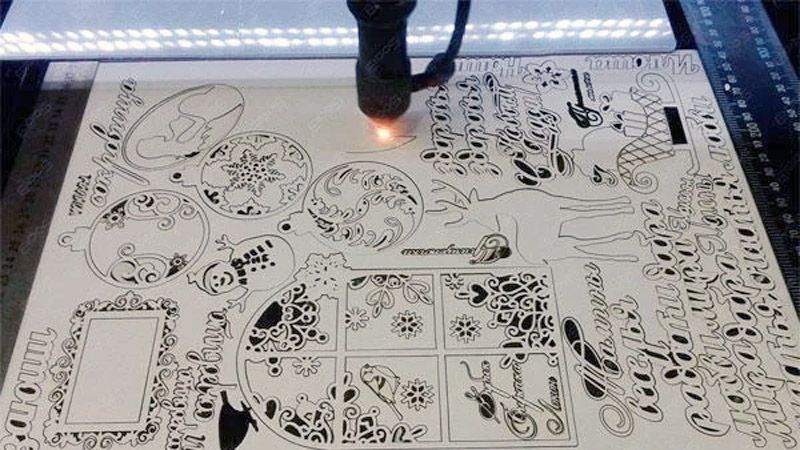

In the modern world, such a service as laser cutting and engraving become more and more in demand. Which is not at all surprising, because it the best way to accurately cut material along the contour. Thanks to the procedure, you can get a quality product with a smooth cut in the shortest possible time..

Lasercraft – high quality laser cutting at an affordable price!

Highly qualified specialists of Lasercraft will not only technologically and quickly fulfill any of your orders, but they will tell everything, what you need to know about cutting and cutting sheet materials. For the manufacture of plastic parts, plexiglass, PVC, wood, plywood, Particleboard and MDF, aluminum and composite materials are most often used by laser cutting or milling cutting of sheet materials.

Experts around the world believe, that one of the most accurate ways to cut various materials is laser cutting. Processing of materials using a laser allows you to do the work better and more accurately. Laser cutting has other benefits too.

- The treated surface does not require additional cleaning after cutting, it means, that the parts are already ready for assembly.

- Modern equipment allows you to carry out cutting work, cutting and processing various materials in the shortest possible time. Which is very important, the latest cutting complexes make calculations as accurate as possible, with a smaller cut tolerance, and this allows you to avoid scrap and make production less costly.

- When laser cutting sheet materials, it is possible to manufacture products in any quantity - from single pieces to large batches.

- Due to the lack of mechanical contact between the equipment and the material, it is possible to cut even easily deformable, fragile or, conversely, too hard parts. This allows you to process 3D parts., such as pipes, eg.

In the manufacture of a variety of layouts and details, creativity is essential.. New imported equipment makes it possible to manufacture complex, and even volumetric figures.

The Lasercraft team are professionals, who know the specifics of equipment and love their job.

The list of works performed is quite wide:

- cutting and milling materials;

- cutting bulk objects (letters, signage and other);

- production of various hinged facade panels (cut, milling and bending);

- execution of technical details according to drawings.

Besides, at the request of the customer, it is possible to perform advertising stands, advertising pillars, outdoor facilities, metal plates, pointers, plexiglass coasters. And also you can order from specialists cutting sheet materials and the implementation of various drawings.

Lasercraft – original solutions to the most non-standard tasks quickly and efficiently! call +38 050 338 00 01.