Inverter welding machines – these are complex devices, much more perfect, than the old transformer type models. Although the price is higher, inverter semi-automatic welding is a very functional tool, having many advantages. It does well with lower quality electrodes, not sensitive to voltage drops, reliable and extremely durable.

Inverter welding machines are readily used as professionals, and amateurs, because they are multifunctional devices, suitable for all. You wonder, which welding inverter to choose and what to consider when buying? In the article below we will explain, what is worth paying attention to.

Choosing the current strength of the inverter welding machine

Current strength, undoubtedly, is the most important parameter for every inverter welding machine (and not only). The higher the amperage, the thicker materials can be cooked. In this way, can say, that with increasing current strength, the degree of versatility of the inverter welding machine increases.

However, it is worth considering, that more powerful equipment will also be more expensive and advanced, and not every welding lover will immediately need a top quality device. So what amperage in the welding machine you should choose?

- 160 BUT – only for small, periodic and short welding works (wire, thin materials). Difficulty handling hinge welding and similar work.

- 250 BUT – allows you to perform the vast majority of work. Devices on 250 And they are successfully used not only at home and in the country., but also on construction sites or car services. Inverter welding machines with such amperage have a really high power., which gives a lot more possibilities to use.

- Over 250 BUT – inverter welding machines with this amperage are mainly used by professionals. They are too advanced for hobbyists and very expensive at the same time.. For amateurs, it is best to buy a welding machine at 250 BUT.

What is better to buy – inverter or transformer welding machine?

Inverter and transformer welding do the same job. The difference between the two devices is primarily in the price.. A transformer is cheaper than an inverter. Besides, it has a simpler construction, so – with the appropriate skills – you can repair it yourself. However, this should not be done during the warranty period., since breaking the seals in the device leads to loss of warranty.

Inverter welding semiautomatic devices – improved version of transformer welding. they are easier to, convenient, easier to operate, resistant to fluctuations in mains current parameters. It means, that they can withstand even very large fluctuations in electricity, unlike transformer.

Types of inverter welding machines

Inverter semiautomatic welding machines are divided into three types (like transformer welding machines):

- MIG-MAG inverter welding machines – in these devices welding takes place in a gas atmosphere. This technique allows you to work with different types of materials., including aluminum. However, it is worth remembering, that the quality of welds may not be the best.

- MMA inverter welding machines – Coated electrodes are used for these devices. However, it is worth remembering, that during the welding process a lot of slag is formed, which settles on welded objects, so it needs to be removed immediately. The joint is not on 100% ideal and aesthetic, but this is not always a problem. MMA inverter welders are ideal for welding in tight spaces.

- Inverter TIG Welding Machines – this type of welding machine allows you to obtain truly aesthetic and smooth welds thanks to non-consumable electrodes. TIG welding machines are ideal for welding high alloy steel and aluminum. It is worth remembering, that every TIG inverter can also work in MMA mode, what, undoubtedly, is a great advantage of this type of equipment.

What is a good inverter welder for home to choose?

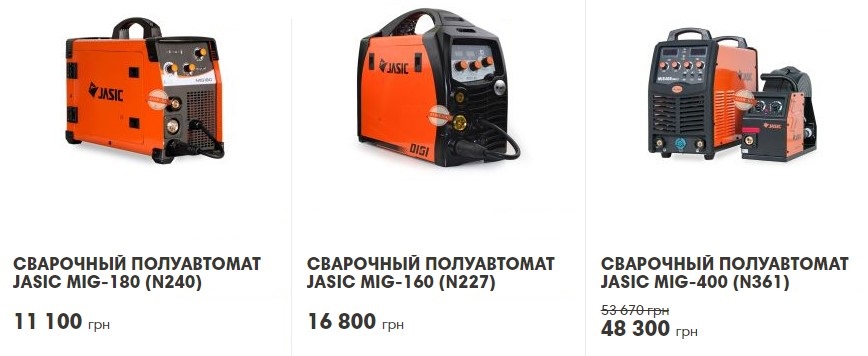

Inverter welding machine – rather expensive device, and the cheapest of them cost from about 10 000 UAH. However, this type of equipment has a low current. Among them, you can find really good solutions from well-known and respected manufacturers.. When buying an inverter welding machine, it is worth considering what work will be done with it..

Most popular option – this, of course, MMA welding. We recommend paying attention to the following models:

Least common type of welding – TIG, but not because of the quality, but because of the high price.

Choosing a specific model of the welding machine, ok also check electrodes prices, because for some types of welding machines, electrodes are really expensive. The higher their quality, the, of course, the price will be higher.

Finally, a few words about the warranty period. Typically, inverter welders come with a two-year warranty., but some manufacturers offer extended warranty. This option is worth considering, since the repair of advanced inverter welding machines – difficult case, laborious and expensive.